Why Doesn’t The US Have High-Speed Rails?

Many European and Asian countries use high-speed rail systems with trains traveling over 200 mph, making long-distance travel easier and decreasing the dependence on automobiles.

So why can’t we do this in the United States?

While regional projects are in the works, the limited development of high-speed rail in the United States can be attributed to a combination of economic, political, and logistical challenges.

Cost and Funding of High-Speed Rails

Implementing a high-speed rail network requires a massive upfront investment in infrastructure.

Building dedicated high-speed rail lines, upgrading existing tracks, and constructing stations involve significant costs.

Securing funding for a project this big can be challenging, especially with so many other competing priorities for limited government resources.

Political Challenges of High-Speed Rails

Infrastructure projects this big often face several political challenges.

The bureaucratic hurdles and ever-changing priorities of different administrations can hinder the long-term planning and sustained investment required for high-speed rail projects.

Competition with Other Transportation

The United States already has a well-established and heavily used highway system, as well as a comprehensive domestic air travel network.

These existing transportation modes are deeply ingrained in American culture, and there may be resistance from citizens and competing companies to invest in high-speed rails as an alternative.

The Population Density Problem

High-speed rails are most effective in regions with high population density, where there is a significant demand for frequent and fast transportation between major urban centers.

In the U.S., population density varies across regions, and some areas may not have the critical mass of passengers needed to make high-speed rail economically viable.

Shared Tracks and Infrastructure

High-speed rails would either need to share tracks with existing freight and commuter rail services or build their own tracks altogether.

This video illustrates the challenges and difficulties of infrastructure in the US and why it’s difficult to build high-speed rails.

Coordinating schedules, upgrading infrastructure, and addressing safety concerns associated with shared tracks can complicate the implementation of high-speed rail.

Size of the Country

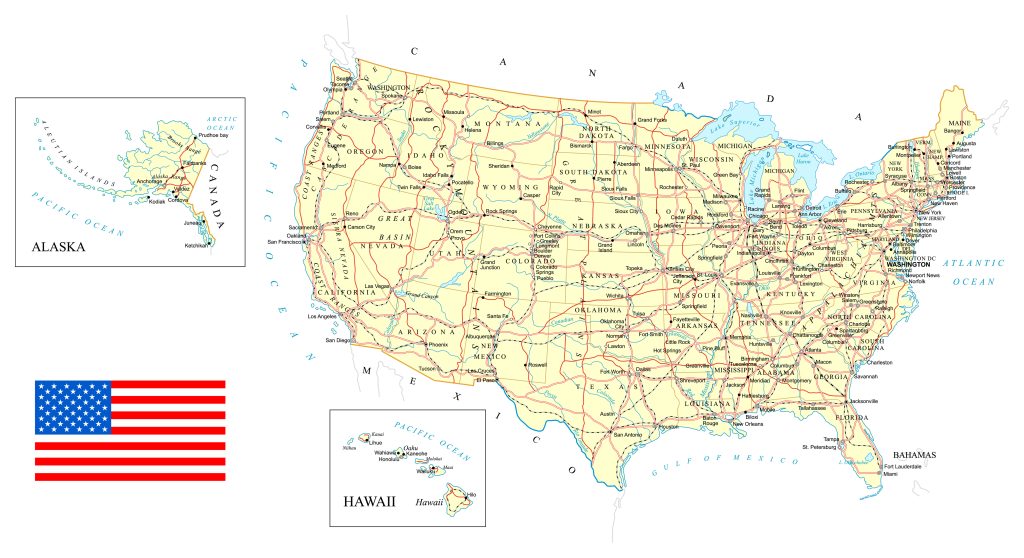

The sheer size and environmental obstacles of the United States pose a unique challenge for high-speed rail.

Covering long distances quickly is more challenging in a country of this scale compared to smaller, more densely populated nations where high-speed rail has been successfully implemented.

Regional High-Speed Rail Projects in the Works

Recently, the Biden Administration announced $8.2 billion in grants to improve existing high-speed railways and create new high-speed railways across the country.

One of the biggest objectives is to create a brand-new high-speed rail system from Nevada to Southern California, which could serve an estimated 11 million passengers annually.

Other states receiving major upgrades include Virginia, North Carolina, Illinois, Pennsylvania, Maine, Montana, and Alaska.

R&S Track Construction in the Midwest

While there have been many proposals for high-speed rail projects in the U.S., overcoming these challenges requires a concerted and sustained effort from the government, private sector entities, and the public.

It seems like things are progressing under the current administration, but only time will tell if these projects will be completed.

R&S Track Maintenance has been serving the railroad maintenance and construction needs of the Midwest for over 30 years.

Contact us at 402-563-2350 for more information.